9 September 2024

Stripping Alloy Wheels: RAL-EST’s Success with METALSTRIP 1333/1

Stripping alloy wheels is a key process for ensuring high-quality repainting and extending the lifespan of automotive wheels. The Estonian company Ral-Est OÜ, an official distributor of ALIT Technologies Spa, offers chemical stripping solutions for alloy wheels and other metal products in the Estonian market. Over the last nine years, Ral-Est has provided complete technical solutions, including equipment and chemicals for chemical stripping alloy wheels.

Ral-Est’s Early Journey into Chemical Stripping

Ral-Est’s CEO, Olev Ustinov, shared insights on the company’s journey. “When we started, chemical paint stripping was relatively unknown in the Baltic region. We were the first to introduce these solutions to Estonia,” Ustinov explained. Initially, the company partnered with a North American supplier, but faced several challenges, prompting them to seek better solutions. Collaborating with the Estonian Institute of Chemistry, they tested various products, and eventually, ALIT Technologies Spa emerged as the best provider of paint stripping chemicals and technology.

Customized Solutions for Efficient Stripping Processes

Ustinov emphasized the importance of not only quickly and accurately stripping products but also offering tailored technical solutions to meet customer needs. ALIT’s support has been crucial in achieving this goal, providing innovative equipment and chemicals that enhance efficiency and reduce costs.

A Case Study: Success with Metalstrip 1333/1

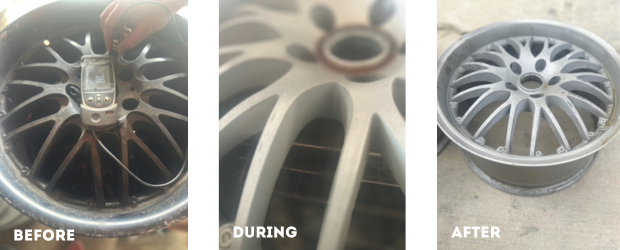

A prime example of this collaboration is a recent case involving spray paint removal for alloy wheels. A Ral-Est customer was experiencing long cycle times and deteriorating bath quality with a competitor’s paint stripper. Ral-Est proposed ALIT’s Metalstrip 1333/1, an alkaline, water-free chemical stripper, particularly effective for aluminum. Applied via spray at 70°C, Metalstrip 1333/1 significantly reduced stripping time and extended the life of the stripping bath, making the process faster and more cost-effective.

Feedback and Performance Results

Feedback from Ral-Est’s own paint stripping plant, as well as end customers, highlights the product’s success in stripping alloy wheels. Typical paint removal times range from 15-30 minutes for Chinese-manufactured wheels, and 30-120 minutes for German wheels, depending on paint thickness. After stripping, a rinse stage ensures the wheels are clean and ready for repainting.

Maintenance and Optimization for Stripping Baths

Ustinov noted that the key to optimizing the performance of the chemical stripping bath is maintaining proper alkalinity with Metalstrip AKTIVATOR 1533 and regularly filtering out paint sludge. This maintenance ensures the bath lasts longer, improving both efficiency and cost-effectiveness.

Ramping Up Success with Metalstrip 1333/1

The results from using Metalstrip 1333/1 have been overwhelmingly positive, sparking enthusiasm within the Ral-Est team. Following these successful outcomes, Ral-Est has ramped up marketing efforts and customer visits within the Estonian painting industry, positioning themselves as leaders in chemical stripping alloy wheels and related services.

A Partnership Built on Mutual Success

As ALIT’s regional manager, Bojan Stevanovic, concluded, the partnership between ALIT and Ral-Est is built on mutual satisfaction, professionalism, and a commitment to supporting customers with the best paint stripping solutions available.

Ral-Est continues to deliver high-quality chemical stripping services, ensuring alloy wheels are efficiently and effectively stripped, prepared for repainting, and made to last.