13 January 2026

What Is Industrial Paint Stripping? Techniques, Benefits, and Risks

Paint stripping, also known as paint removal, is an essential process in the metalworking, automotive, and industrial sectors. It removes coatings, paints, or powder layers from metal surfaces, restoring them for reuse or preparing them for a new finishing cycle. This operation plays a key role in maintenance and sustainability, extending the life of metal components and production tools.

👉 Discover our complete guide to chemical paint stripping

What is Paint Stripping?

Paint stripping is the process of removing paint or coating layers from materials such as steel, aluminum, zinc, or magnesium.

While paint stripping and paint removal are often used interchangeably, the difference lies in the method and application:

- Paint stripping refers to physical, chemical, or thermal removal of paint;

- Paint removal can also include surface preparation or cleaning procedures.

It is a critical step for maintaining hooks, fixtures, and metallic parts used in coating or painting lines.

Benefits and Risks of Paint Stripping

Benefits

- Surface recovery and reuse: stripping allows components to be reused, reducing waste and replacement costs.

- Preparation for new coating: a properly stripped surface ensures uniform and durable adhesion for the next finishing layer.

Risks

- Toxic substances: traditional stripping agents may contain hazardous solvents or vapors if not handled with proper safety systems.

- Surface damage: using the wrong method for the material may compromise its structural or aesthetic integrity.

Safety and Ecology

Modern technologies allow safe and eco-friendly paint removal.

Low-impact solutions, free of chlorinated solvents and equipped with fume containment systems, represent the most advanced path for sustainable industry.

Paint Stripping Techniques

Chemical Paint Stripping

Chemical paint removal (or chemical stripping) uses specially formulated products to dissolve paint without damaging the metal substrate.

It’s the most common technique for hooks, masking tools, and complex components.

👉 Learn more about chemical paint stripping and its benefits

Mechanical Paint Stripping

Mechanical paint stripping uses abrasion, blasting, or brushing. It’s effective on robust materials but can be too harsh on light alloys.

👉 Compare mechanical and chemical stripping methods

Thermal Paint Stripping

Thermal paint stripping (or heat stripping) applies high temperatures to carbonize the coating, making removal easier.

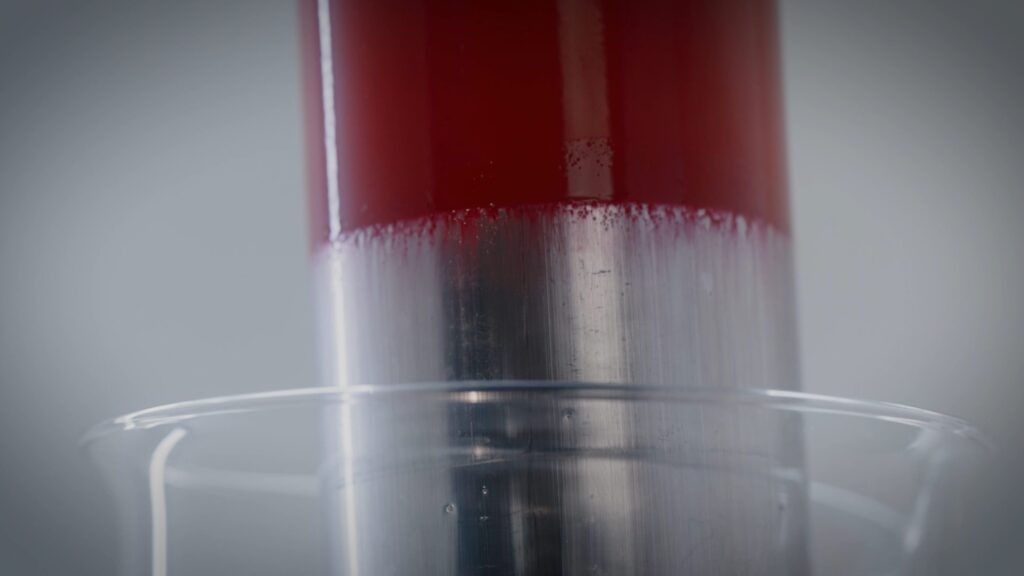

Immersion Paint Stripping

Dipping paint removal or immersion paint stripping uses heated tanks to process large batches of components uniformly.

Ultrasonic Paint Stripping

Ultrasonic paint stripping uses high-frequency sound waves to enhance the chemical bath’s efficiency, reducing treatment time.

Fluidized Sand Bed Paint Stripping

Fluidized sand bed paint stripping combines heat and suspended sand to remove cured coatings, effective but suitable only for durable materials.

Powder Coat Paint Stripping

Powder coat paint stripping focuses on removing powder coatings (epoxy, polyester, polyurethane) from metal parts such as frames and wheels.

Paint Stripping on Metals and Coatings

Metals

Metal paint stripping and chemical metal stripping are used on steel, iron, aluminum, zinc, and light alloys. The chemical method is the most precise and controllable.

👉 Guide to metal paint stripping

Aluminum

Aluminum paint removal requires specific formulations that protect the metal’s brightness and surface integrity.

👉 How to safely remove paint from aluminum

Alloy Wheels and Rims

Alloy wheel stripping or rim paint stripping is widely used in the automotive aftermarket, where the aesthetic finish is crucial.

👉 Techniques for alloy wheel paint stripping

Coatings

Coating stripping applies to polyurethane, epoxy, or polyester coatings, each requiring a customized approach for optimal performance and substrate protection.

Applications and Sectors

Automotive

Automotive paint stripping regenerates frames, rims, and components, ensuring efficiency and safety in production and maintenance.

Industrial

Industrial paint stripping supports maintenance and recovery of structures, machinery, and production lines.

Commercial

Commercial paint stripping is used in furniture manufacturing, design, and light construction industries.

Conclusions

Paint stripping is more than just paint removal, it’s a key technology for productivity, sustainability, and surface quality.

Choosing the right method, chemical, thermal, or mechanical, depends on the material, precision required, and desired environmental impact.

👉 Explore our related sections:

- Chemical paint stripping

- Safe and eco-friendly paint removal

- Metal paint stripping

- Industrial applications