3 September 2025

The most versatile paint stripper on the market: suitable for every surface, system, and coating.

When we developed Metalstrip 1334, we aimed for one thing: practicality. A stable, effective, easy-to-use formula. A product that does its job well, with intelligence and versatility.

The result? A medium-temperature stripping solution that now works quietly in many plants, optimizing cycles, reducing waste, and restoring surfaces ready for a new life.

Strategic versatility

Metalstrip 1334 is a medium-temperature chemical paint stripper (40–75 °C) designed to act on a wide range of coatings, from thermosetting powder paints (polyester, polyurethane) to liquid paints.

It removes coatings selectively, without damaging metal surfaces, including ferrous alloys, aluminum alloys, and yellow metals.

It ensures operator safety, environmental protection, and long-term chemical stability of the bath. It’s ideal for aluminum profile stripping and works effectively in both immersion and spray systems.

But the real strength lies in its operational flexibility.

Metalstrip 1334 is compatible with all major ALIT systems: it performs efficiently in spray systems like FASTRIP S, as well as in immersion systems with ultrasound (FASTRIP T2), mechanical agitation (T5), or automated movement of parts (MT, AP).

Simplified management

One of the most common issues with stripping baths is rapid solution degradation.

Not with 1334.

Its ability to retain large amounts of dissolved paint extends the bath’s life, reducing system downtime. Combined with FASTRIP FP filtration systems, it ensures long-term performance, both in stripping effectiveness and surface quality.

There’s also an often-overlooked factor: energy.

This system offers an energy-saving advantage: operating at lower temperatures reduces heating costs without compromising performance or stripping time, which remains in line with production needs.

Several customers have confirmed excellent results at around 50 °C. But there’s a double benefit: lower evaporation also significantly reduces chemical consumption.

In short: lower operating costs and better energy sustainability.

Where it really works: real-world applications

Metalstrip 1334 is already delivering excellent results across various production environments.

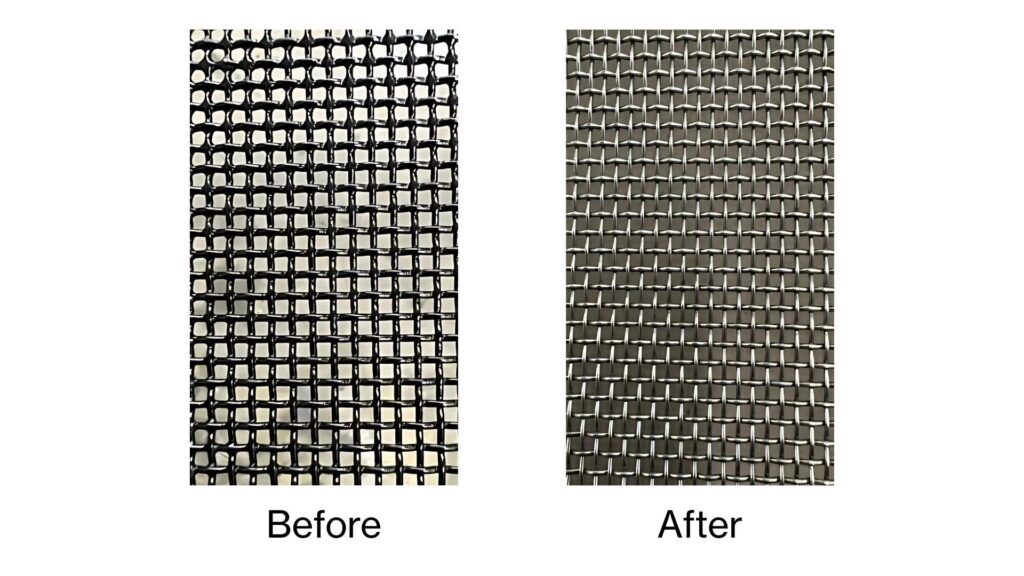

In a facility in Southeast Asia specializing in stainless steel and perforated aluminum mesh, Metalstrip 1334 played a key role in reactivating a long-idle stripping line.

The system had been shut down due to high operating costs and previously ineffective chemicals.

Thanks to the Metalstrip 1334 + FASTRIP FP filter press combo, the process was fully optimized.

Tests showed that immersion at 50 °C with mechanical agitation achieves complete stripping in 30–60 minutes.

Surfaces come out clean and undamaged.

Where the bath once had to be replaced monthly (producing over 8 tons of waste), it now runs continuously with only simple top-ups, cutting environmental impact and management costs.

The perfect balance between performance and savings

There’s no one-size-fits-all formula in paint stripping, and no single “perfect” temperature.

Each plant has its own pace, balance, and needs. That’s why at ALIT, we talk about tailored approaches, not ready-made solutions.

Metalstrip 1334 was developed with this mindset: a solid, reliable tool that adapts to the context.

It reduces waste, simplifies bath management, and helps control hidden costs that often go unnoticed in initial assessments.

It’s not designed to disrupt processes, but to improve them, steadily and concretely.

And sometimes, choosing a more coherent chemical solution is exactly what makes the difference.