EVERY DIFFERENCE MATTERS

The second issue of UNCOATED is finally here 👉 UNCOATED Vol 2 July 2025

UNCOATED is back, and this time, with an even stronger conviction: in our sector, and in business life in general, every difference matters.

After the first issue, which marked the beginning of a new way to talk about industrial paint stripping, this second chapter takes things further. Inside, you’ll find who we’ve become: a company in motion, with new projects, new people, and new challenges tackled side by side with clients and partners.

You’ll also find a very clear idea of the future. One built on sustainability, regulatory awareness, and innovation, in products, in processes, and in the way we approach stripping.

UNCOATED isn’t just a magazine. It’s an invitation.

To tell the real stories of work. To share experiences, doubts, and milestones. To build relationships that go beyond roles and stand the test of time.

Once again, this year, we’re proud to support Verona Volley as an official sponsor.

But our commitment goes far beyond a logo on a jersey; it’s a choice rooted in shared values and a deep connection to our territory.

Verona is the city where we were born, where we grew up, and where we continue to build our future, day after day.

Supporting the city’s top volleyball team also means giving back to a community that has given us so much. It means believing in a project that combines sports passion with real, tangible growth, on and off the court.

Like business, volleyball thrives on consistency, teamwork, and the drive to improve.

That’s why this partnership feels so natural to us: because we see in sport the same values that inspire our work every single day.

And then there’s the most exciting part: sharing the thrill of each match with the people who believe in us.

Every season, we reserve seats in the stands for our clients and partners, to enjoy, together, the energy of a stadium that comes alive at every point.

Not all improvements stem from a problem. Sometimes, they are the result of a conscious decision: to work better, faster, and with greater control. That’s the case of Sverniciatura Veneta srl, a company founded in 2007 and specialized in third-party chemical stripping of aluminium components and metal hardware. At the helm is Nicola Moratti, sole administrator, with a clear objective: to offer a fast, reliable, and technically solid service.

The change was not driven by an emergency, but by a strategic decision: to shorten processing times and ensure greater uniformity in results. Two key factors to respond even more promptly and reliably to customer demands, especially in the case of rework or urgent jobs. While immersion stripping was stable, it took over three hours to process a batch of wheels, an unsustainable timeframe in a dynamic production environment. Moreover, manual handling introduced variability that could affect process repeatability.

Together with the Sverniciatura Veneta team, and thanks to a long-standing trust-based relationship between our CEO Loris Rossi and Nicola Moratti – we defined a clear path: reduce processing times and ensure stable, controllable quality throughout the process.

The answer was FASTRIP S, our vertical spray system designed for fast, safe, fully automated chemical stripping cycles. Compact and modular, it integrates easily into existing production lines and is ideal for treating both light and ferrous metal components. Process temperatures are adjustable between 80°C and 150°C, depending on the metal and the coating, with continuous monitoring of all operational parameters.

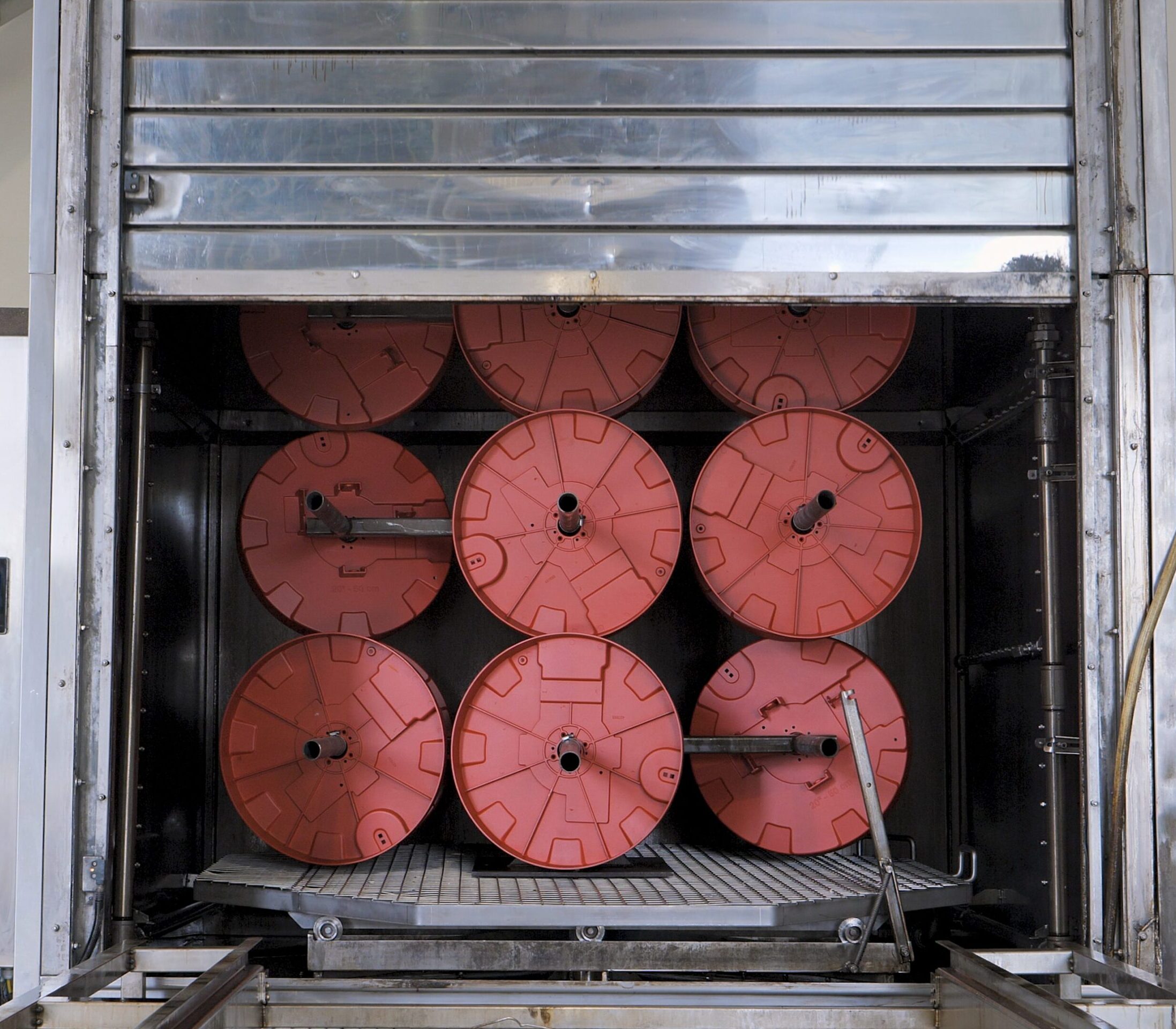

Parts are loaded into metal baskets and remain stationary throughout the entire cycle, eliminating manual handling. This increases safety and reduces the risk of dents or mechanical damage. Uniformity is ensured by a high-efficiency spray system that distributes the chemical solution evenly across all surfaces.

Thanks to FASTRIP S, Sverniciatura Veneta can now strip 120 motorcycle wheels in just 20 minutes. A dramatic improvement that has transformed production scheduling. Reworks can be handled within the day, and urgent jobs no longer disrupt overall planning. The system is compatible with FASTRIP FP filtration units, which extend the lifespan of the chemical solution, and it operates with either electric or diathermic oil heating. All of this with low energy consumption and full Industry 4.0 integration capabilities.

Meanwhile, our laboratory developed the most suitable chemical formulation for Sverniciatura Veneta’s needs. After an in-depth testing phase – both in the lab and in real-scale applications, the chosen solution was METALSTRIP® 1728/3, a high-performance stripper specifically designed for high-temperature spray systems like FASTRIP S. The water-based formula, free from chlorinated compounds and phenols, operates between 120°C and 150°C, ensuring rapid and selective removal of organic coatings with maximum compatibility on light alloys, steel, and galvanized surfaces.

The solution is stable over time and regenerable, a feature that enables tighter process control, lower product consumption, and a more sustainable cycle overall. The process is also safer, both for the environment and for operators. Today, the active cycle removes coatings with precision and control, preserving the substrate and improving overall repeatability and process efficiency.

This project is more than just a system upgrade. It is the outcome of a long-standing relationship built on trust, a hands-on technical partnership, and a shared belief that every process, even the most established, can always be improved.

ALIT TECHNOLOGIES SpA - Via Cavalieri d'Italia, 7 - 37047 SAN BONIFACIO (VR) ITALY - VAT IT03341620247 | Company Details - Privacy Policy - Cookie Policy - Credits