Click here 👉🏼 and watch the full process on our youtube channel

ALIT’s response with Fastrip T5 and T5 Multitank immersion systems

The chemical paint stripping process for alloy wheels is one of the most delicate operations in the regeneration of automotive components. By their very nature, alloy wheels require highly controlled and specific processing conditions: when it comes to paint removal, it cannot be reduced to the simple concept of stripping, but must take into account the overall balance between material, geometry and surface treatment.

Alloy wheels are mainly manufactured from aluminum alloys, sometimes with the addition of magnesium or other metals to improve mechanical strength and reduce weight. Compared to steel wheels, they are lighter, offer better heat dissipation and feature greater aesthetic and geometric complexity.

For this reason, surface treatments must be extremely controlled and application specific. Alloy wheels are generally protected by multi layer coating systems (primer, base coat, color and clear coat), do not tolerate aggressive methods such as uncontrolled blasting and require dedicated chemical stripping solutions capable of removing the coating without attacking the metal or generating surface defects.

Immersion paint stripping as a process choice

Within the scope of this article, chemical immersion paint stripping represents one of the most controllable and effective solutions for alloy wheel treatment. Fastrip T5 and Fastrip T5 Multitank tanks operate according to this principle, allowing wheels to be treated by immersion in dedicated baskets inside a chemical bath specifically formulated for light alloys.

This approach ensures uniform action even on complex geometries and multi layer coatings, reducing the risk of localized attacks or surface defects. The use of a dedicated stripping agent such as the Metalstrip Wheels product line, specifically developed for alloy wheel paint removal, allows selective action on coated surfaces while preserving the characteristics of the metal substrate.

The combination of immersion technology, controlled process management and dedicated chemistry makes this type of system particularly suitable for regeneration and recovery applications in the automotive sector.

Operational sequence of the paint stripping process

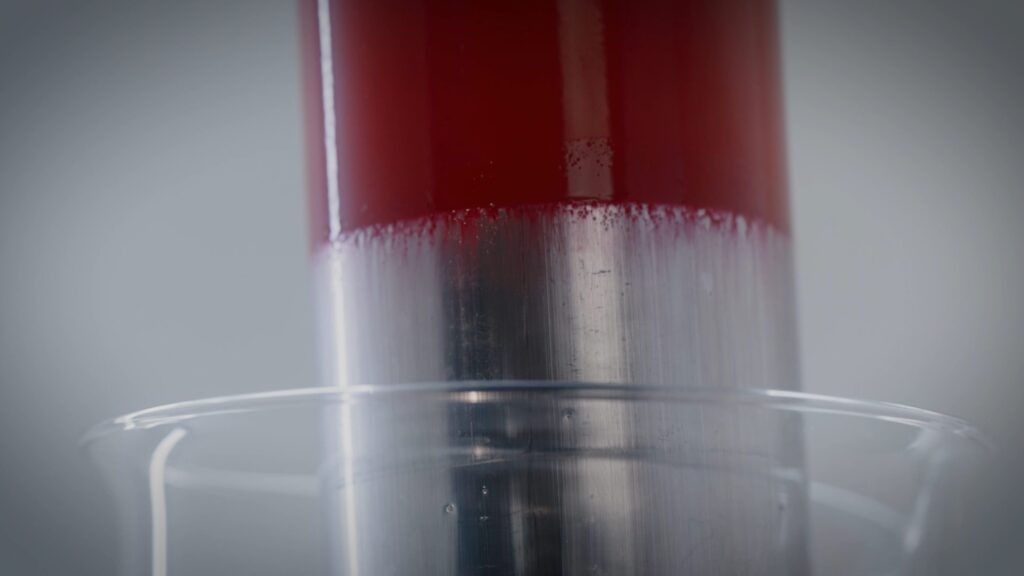

The chemical paint stripping process for alloy wheels using T5 and T5 Multitank tanks begins with the definition of the most suitable stripping solution for the specific application. Before starting the treatment, the Metalstrip Wheels product is selected and validated through laboratory tests carried out on samples provided by the customer, in order to adapt the formulation to the type of coating, number of layers and wheel alloy to be treated. Only after this validation phase is the stripping solution used in the industrial process.

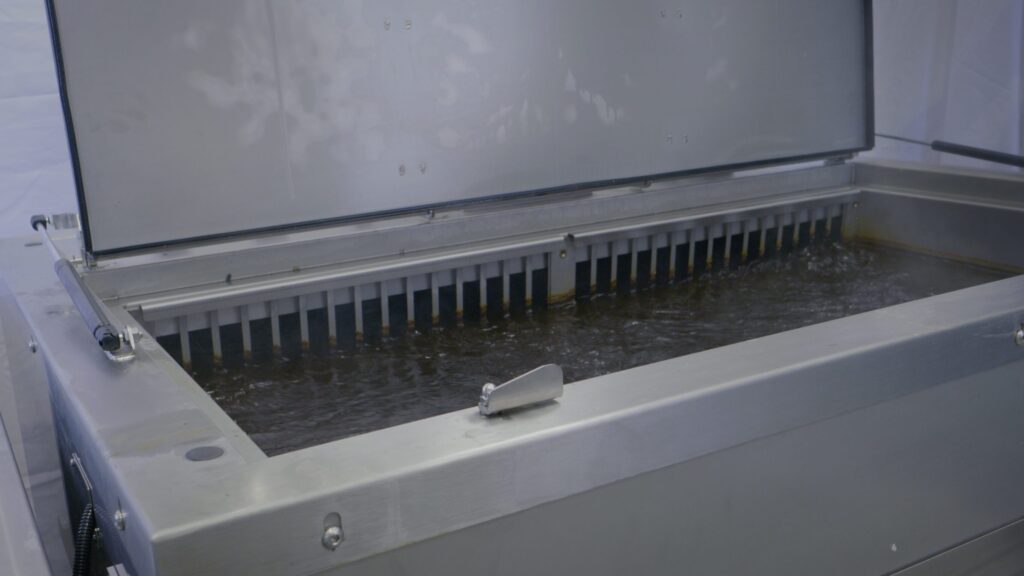

Once the correct formulation has been identified, the tank is filled with the stripping solution and started up, bringing the bath to the set operating temperature. The insulated and sealed tank ensures the thermal stability required for effective treatment. Once operating conditions are reached, the wheels are placed inside dedicated baskets and fully immersed in the stripping bath. The tank is then closed and the cycle begins.

During the treatment phase, the combined action of dedicated chemistry, temperature and internal agitation acts selectively on the multi layer coatings, promoting paint detachment without compromising the metal substrate. Cycle duration depends on several factors, including the type of coating, coating thickness, operating temperature and the Metalstrip Wheels formulation used.

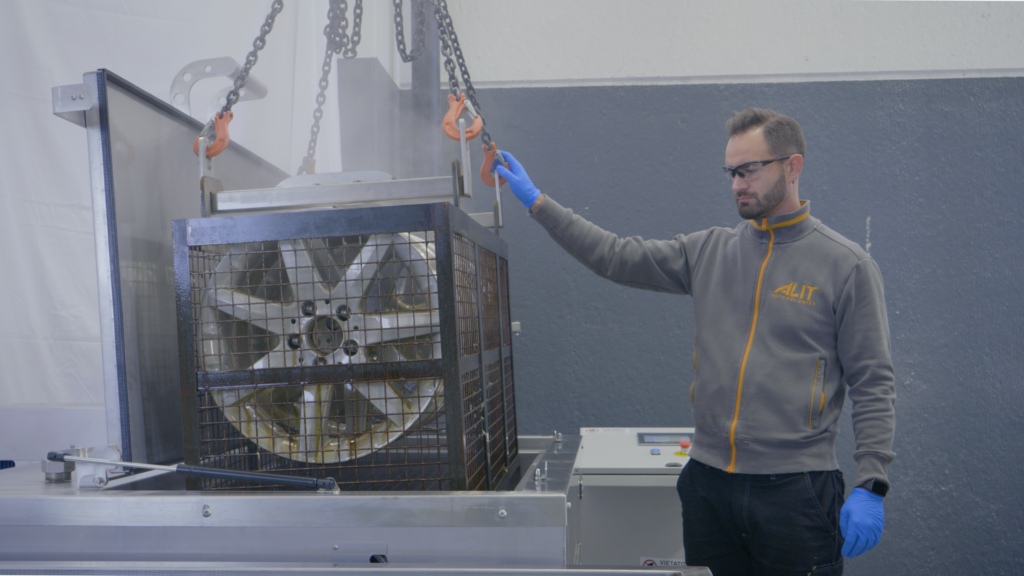

At the end of the stripping cycle, the basket is removed from the tank and the wheels are free of coating and ready for subsequent rinsing operations. In the Multitank configuration, the basket is handled via a lifting system and immersed in a water filled rinsing tank, representing the first stage of chemical residue removal. This is followed by a draining phase and a final rinse performed using a mobile pump unit, used to remove any more persistent residues and complete surface cleaning. In the base T5 configuration, the process focuses exclusively on the immersion stripping phase, while rinsing and handling operations are managed separately.

Advantages of the immersion stripping process

Adopting a chemical immersion paint stripping process using T5 and T5 Multitank tanks provides a range of operational advantages related to process control and stability. Complete immersion of the wheels in the chemical bath ensures uniform action even on complex geometries, reducing the risk of partial or uneven stripping.

Control of process parameters, such as temperature and treatment time, allows the cycle to be adapted to different coating types and wheel configurations, improving result repeatability. The use of dedicated baskets simplifies part handling during loading, treatment and unloading phases, while the integration of rinsing stages in the Multitank configuration enables more orderly and controlled management of post stripping operations.

Overall, the process is compatible with alloy wheel regeneration requirements, reducing the risk of substrate damage and preparing the component for subsequent finishing stages.

Final considerations

Alloy wheel paint stripping requires a structured process approach in which each phase is clearly defined and controlled. The use of immersion systems such as T5 and T5 Multitank makes it possible to address this operation in a way that is consistent with the complexity of the component, integrating dedicated chemistry, parameter control and orderly management of operational phases.

More than simple paint removal, the treatment becomes a technical phase within the regeneration cycle, designed to preserve wheel integrity and ensure repeatable results. In this context, chemical immersion paint stripping confirms itself as a solution aligned with the needs of the automotive sector, where precision, control and process reliability are fundamental requirements.