How much does perfect masking impact the quality of the final finish? Far more than you might think. Proper protection of metal surfaces during painting, cataphoresis, anodizing, and electroplating processes means avoiding rework, reducing waste, and achieving flawless results from the very first try. That’s precisely why MAS-KING was created: to offer effective masking solutions that are easy to apply and instantly available.

Two years after its initial launch, the project has evolved, strengthening its market position and integrating valuable customer feedback. December 2024 marked the perfect time for a rebranding that reflects MAS-KING’s growth and new ambitions. Today, MAS-KING has a stronger, more defined identity while maintaining the practicality and straightforward approach that set it apart from the beginning.

Why MAS-KING?

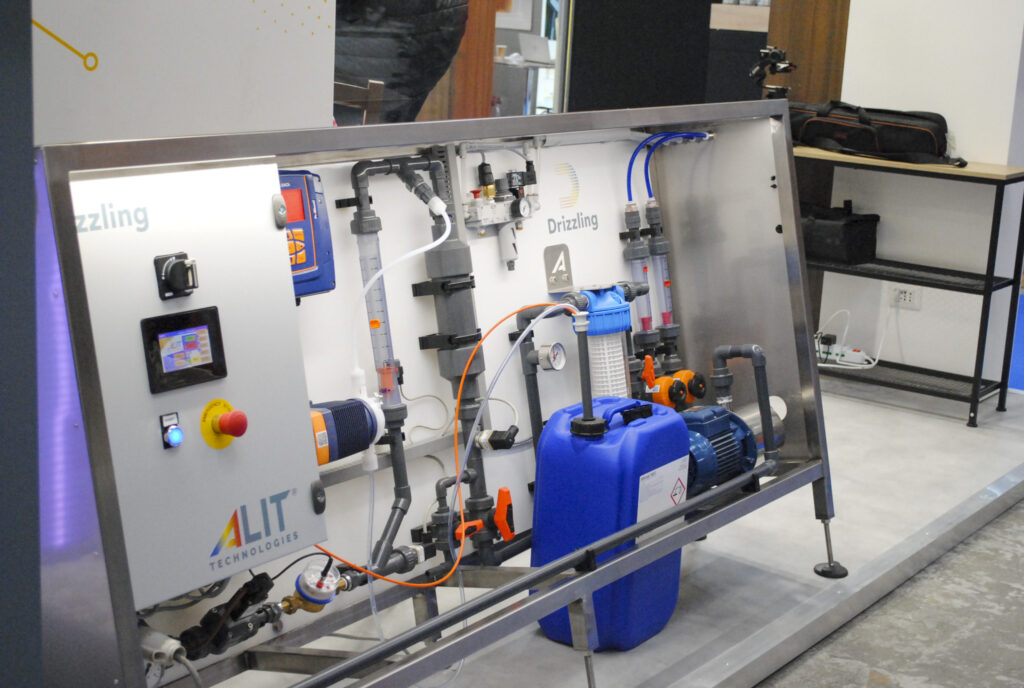

MAS-KING was born from the combined expertise of ALIT Technologies in paint stripping and Alufinish Italia’s experience in surface treatment. This deep technical background enables MAS-KING to thoroughly understand the needs of companies operating in metal finishing and offer genuinely effective solutions. Industrial masking isn’t just about materials—it’s about detailed knowledge of production processes.

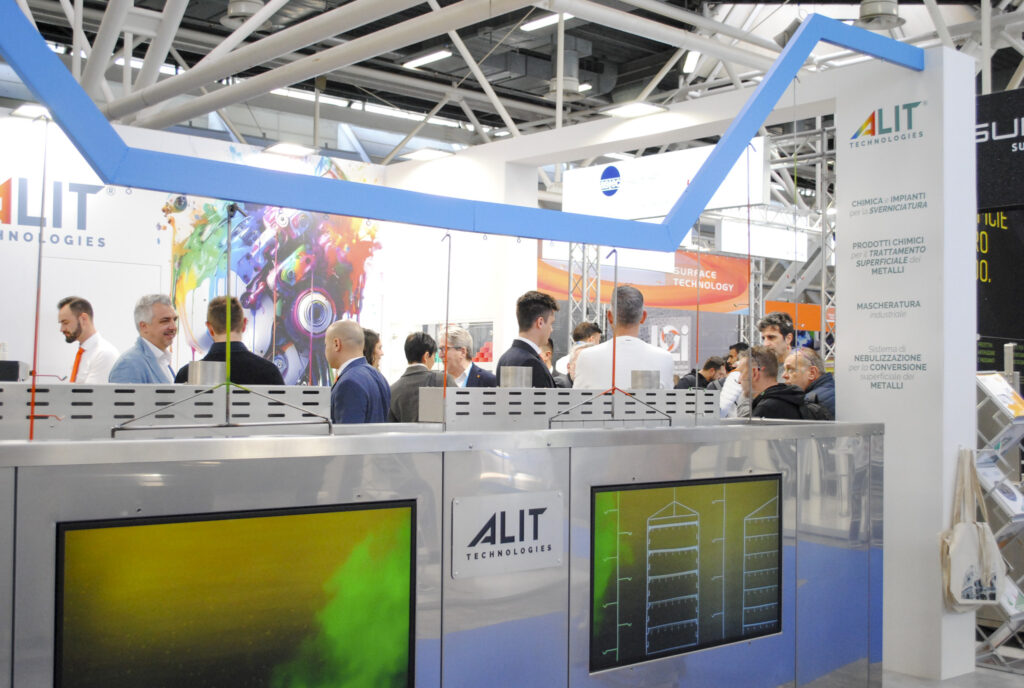

The recent rebranding aimed precisely to reinforce this concept, giving MAS-KING a more recognizable identity and clearer messaging. Its official presentation took place at the MECSPE fair in March 2025, an ideal occasion to unveil the brand’s fresh new look.

Debut at MECSPE 2025

The international manufacturing fair positioned MAS-KING front and center with its new logo and updated product range. Visitors showed high interest, confirming that the brand is moving in exactly the right direction. Elena Giusti, MAS-KING’s Sales Manager, commented:

“We were thrilled with the level of interest MAS-KING generated. It was great reconnecting with longstanding customers and welcoming new contacts who discovered the value of our masking solutions and services.”

Targeted Solutions and New Services

MAS-KING distinguishes itself with a focused, carefully structured catalog. Instead of endless product lists, it offers a thoughtful selection of genuinely useful and practical solutions:

- Silicone and EPDM plugs and caps, resistant to high temperatures.

- Adhesive tapes and labels for precise protection without residues.

- Hooks and accessories for optimal support of parts during painting.

- Can and drum openers designed to streamline chemical product handling.

Alongside these solutions, two innovative services have been introduced to significantly enhance customer experience:

- A physical store: an innovative concept in the industrial masking sector. More than just a retail space, it’s a genuine consulting center where customers can handle, test, and select products tailored precisely to their production processes. Every detail is designed to provide fast responses and personalized service, eliminating the risk of incorrect purchases or long wait times.

- A mobile warehouse: MAS-KING brings masking solutions directly to clients with a fully-equipped van—a true mobile shop. This exclusive service allows customers to test products on-site, supported by a specialized technician to identify the ideal solution. An innovation that drastically reduces procurement times and optimizes the entire production workflow.

The Strength of ALIT’s Sales Network

MAS-KING is more than just a product catalog—it’s a network of specialists supporting companies at every production stage. Thanks to ALIT’s commercial network, MAS-KING is present both in Italy and internationally, with expertise spanning surface pretreatment, painting, and paint stripping. This ensures you have a partner who thoroughly understands production needs and can deliver customized solutions with no margin for error.

MAS-KING Looks to the Future

The rebranding is just a starting point. MAS-KING will continue expanding its catalog and refining its services to address even more precisely the needs of industrial finishing professionals.

MAS-KING isn’t just about masking—it’s a new approach to surface protection, providing practical, accessible solutions for those who strive for efficiency and minimal waste.

Discover more about MAS-KING: The King of Masking!