At ALIT, we’ve been saying it for a long time, and we still believe it: paint stripping should be an integral part of every manufacturer’s internal process. It’s the most effective way to reduce waste, cut costs, simplify workflows, and achieve higher levels of sustainability.

But we know that reality is often more complex.

Some companies run nonstop production cycles with massive volumes. Others simply don’t have the physical space for a system. And some prefer to have a solid, ready-to-go Plan B to manage peaks or unexpected issues. That’s where outsourcing paint stripping comes into play.

But who should you trust? Which paint stripping method is the right one? And how do you make the right choice?

Companies that need to strip paint from their components often face a technical, economic, and operational dilemma. It’s not just about finding a supplier, it’s about finding a reliable partner who can guarantee quality, lead times, sustainability, and real expertise.

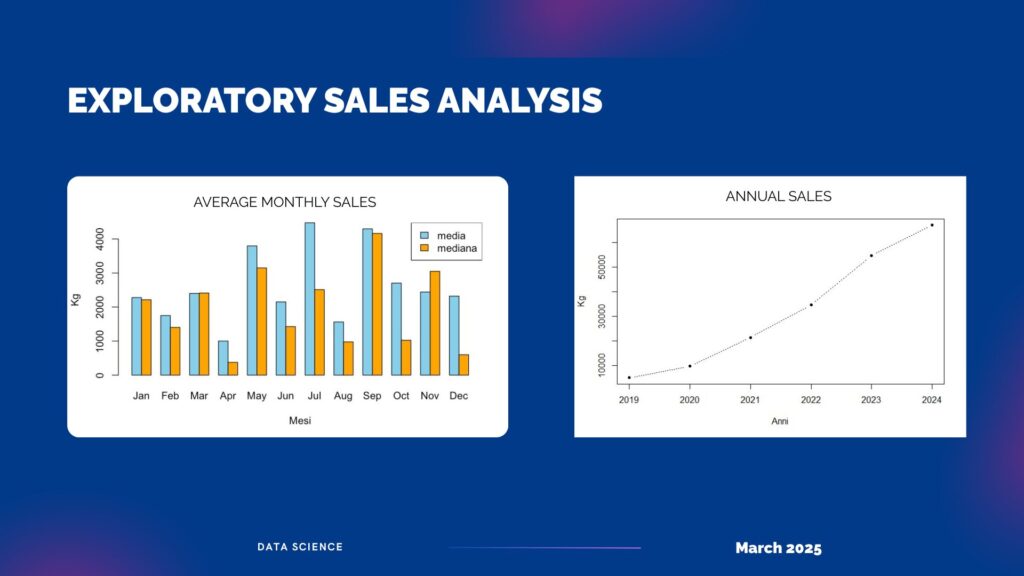

In the industrial world, there are several paint stripping methods. Each has its pros and cons. That’s why understanding what’s behind each process makes all the difference.

Let’s take a look:

- Mechanical paint stripping: This method uses abrasives, sandblasting, or grinding. It’s fast and works well on simple surfaces, but it can damage delicate materials or create surface irregularities. It also produces dust and waste that isn’t always easy to manage.

- Thermal paint stripping: This method uses high temperatures to break down the paint (e.g., pyrolytic ovens). It’s effective on thick or complex coatings but can deform or alter the structure of the part. It also involves high energy consumption.

- Cryogenic paint stripping: This method rapidly cools the surface with liquid nitrogen, making the paint brittle and easy to remove. It’s precise and clean, but costly and not suitable for all shapes or materials.

- Laser paint stripping: This technology uses high-intensity laser beams to remove paint, rust, or coatings from metal surfaces. It’s highly precise and allows for selective removal without damaging the underlying material. Its main advantages include no physical contact and reduced waste, making it an eco-friendly solution. However, it has downsides: high initial investment, limited effectiveness on large or heavily corroded surfaces, and safety concerns due to high-power lasers.

- Chemical paint stripping: This is where chemistry, control, and know-how come into play. Chemical strippers selectively dissolve paint without attacking the metal, allowing precision work on complex components. The advantages are many: low operating temperatures, compatibility with various materials, the ability to recover and regenerate the chemical bath, and consistent results.

The downside? It takes experience. It requires purpose-designed chemical formulas. It demands skill in managing baths, timing, and reactions. And it needs a system built to do it right, with filters, rinses, and constant monitoring.

In short: you need someone who truly knows what they’re doing.

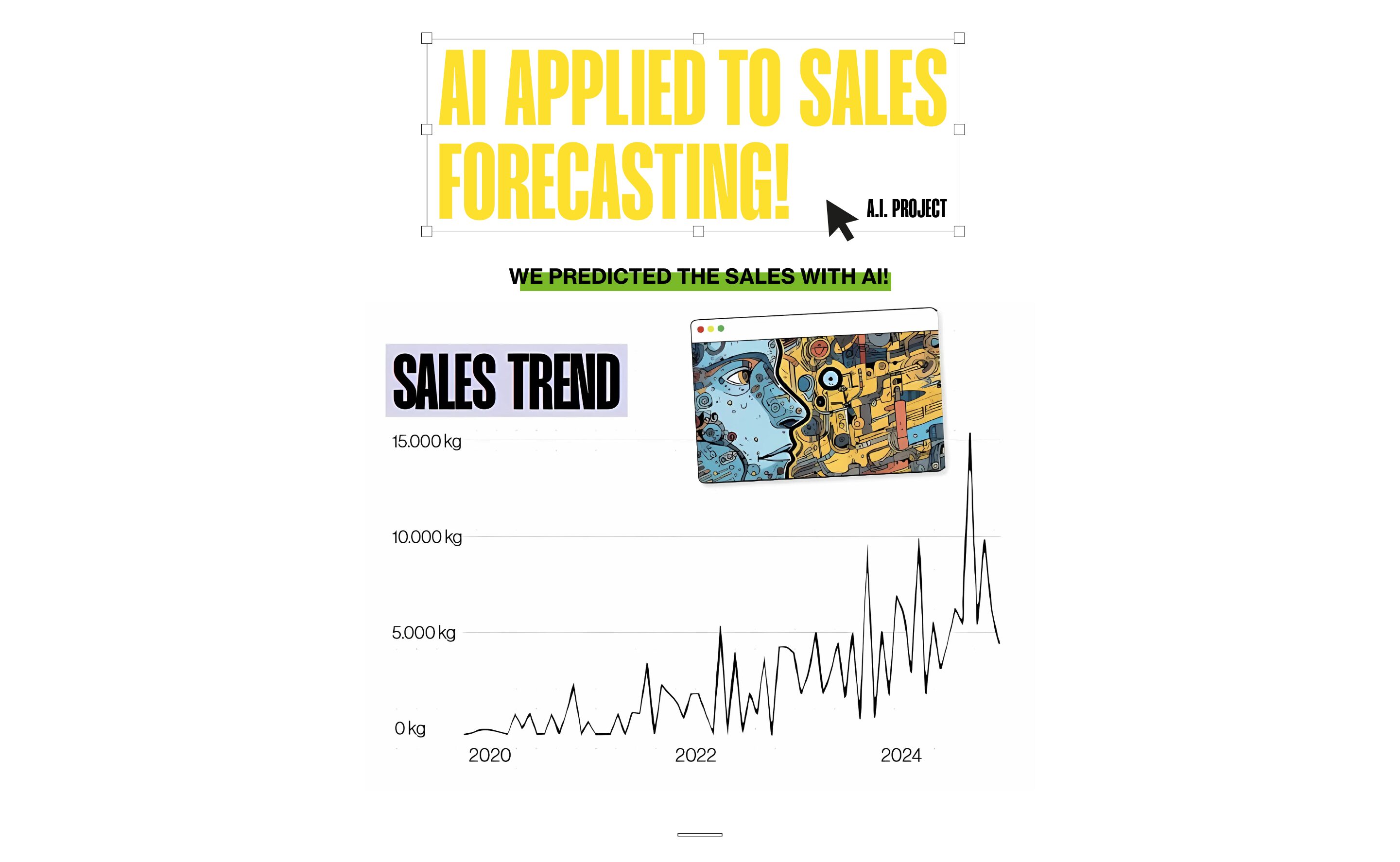

Which brings us to a real-world example worth sharing.

The Value of High-Level Know-How

(Outsourced Paint Stripping Optimized with ALIT Systems: Inside the Serbia Facility)

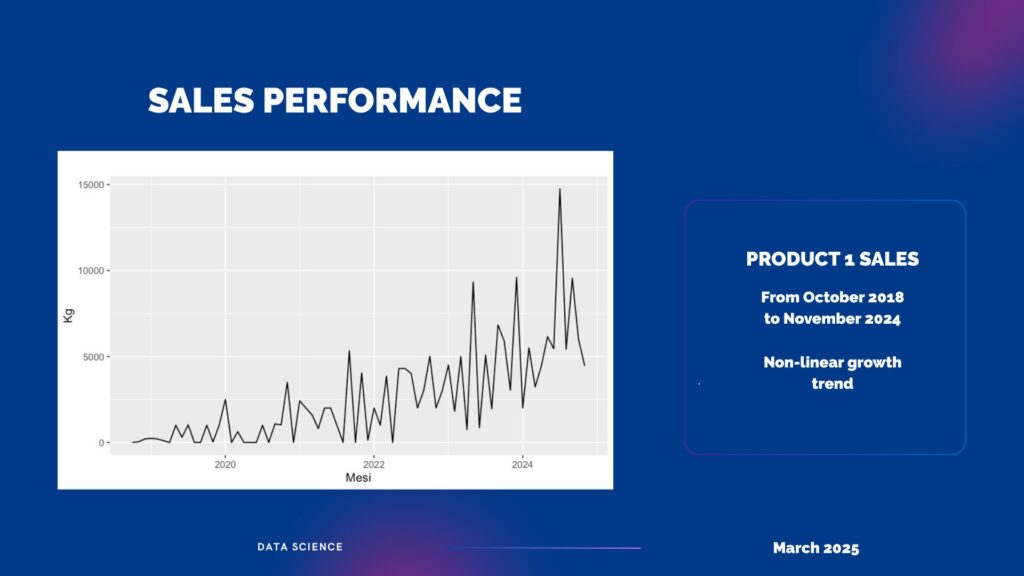

ALIT Service Serbia works daily in the field of outsourced paint stripping, processing thousands of parts each day. Extruded, injected, or stamped aluminum components, bronze, carbon steel, stainless steel, galvanized alloys, Teflon: different materials, different needs, one consistent promise delivered.

Each cycle is handled by skilled, trained staff in a facility equipped with advanced technologies. ALIT Service uses chemical products and systems developed by ALIT Technologies, ensuring consistent quality, sustainability, and process vision.

The plant includes:

- One FASTRIP AP for immersion stripping of aluminum profiles

- One FASTRIP FP system for chemical product filtration and recovery

- Two FASTRIP T5 machines — 75 °C compact immersion systems, ideal for small batches, prototypes, or urgent jobs

On the chemical side, the choice falls on METALSTRIP products: high-performance strippers designed with a clear goal, to ensure not just efficiency, but sustainability too. All ALIT chemicals are developed to be reusable, easy to filter, and low-impact.

ALIT Technologies is actively committed to supporting the goals of the 2030 Agenda for Sustainable Development, an ambitious challenge, especially in the world of chemicals, but one ALIT tackles every day with concrete, measurable solutions.

Chemical baths are filtered up to three times, and residue management is fine-tuned to reduce environmental impact and consumption. The result? Real operational efficiency and true sustainability.

Here’s the most concrete fact: parts ready for repainting in 24 hours. No manual rework, no leftover defects, no delays.

This is where trust becomes action.

And when theory seems far from practice, some prove that the gap can be bridged, without compromise. That a third-party service can meet expectations, even exceed them. That reliability isn’t just a claim: it’s built. Day by day, cycle after cycle, strip after strip.

ALIT Service Serbia isn’t a promise. It’s proof that when a company uses ALIT chemistry and systems, it has everything it needs to meet real production demands: expertise, quality, speed, and sustainability.

So, back to the very first question:

Is it still worth outsourcing paint stripping?

The answer is: it depends.

From a strategic point of view, nothing beats a proper feasibility study to bring stripping in-house. Optimization, control, waste reduction, all of these are key levers that can truly make a difference when managed internally.

But if you need a Plan B because of space issues, production loads, or flexibility, then choosing the right partner is crucial.

And here’s where we can confidently say:

If your supplier uses ALIT systems and certified chemistry, just like ALIT Service Serbia, then risk becomes reliability.

Because trust is built like this: with the right technologies, real skills, and a vision of sustainability that’s no longer optional, it’s a shared responsibility.