In 2024, internalizing paint stripping becomes viable. But, how to choose the right technology, and what are the benefits? This article explores these questions through a case study.

For many companies involved in painting operations, having an in-house chemical paint stripping system can be essential. It can be used to reclaim defective parts and to strip hooks and frames used for hanging the components. In both cases, the ability to perform these operations internally provides significant advantages. For instance, the in-house paint-stripping of parts with surface defects is quicker, allowing for prompt reprocessing and avoiding delivery delays. Similarly, the in-house chemical paint-stripping of hooks instead of relying on external contractors, brings about clear benefits. The turnover of hooks becomes more regular and consistent, resulting in a better paint quality, and avoids the typical damages associated with thermal or mechanical stripping.

ALIT TECHNOLOGIES SpA, a leading provider of chemical paint stripping products and systems for metals, has introduced the comprehensive FASTRIP T5 MULTITANK system to meet the growing demand for internal paint stripping. The system includes a chemical stripping tank from the T5 series and a set of modular accessories tailored to the customer’s specific needs. With FASTRIP T5 MULTITANK, parts to be stripped can be loaded into specially designed baskets, lifted with the overhead crane, and effortlessly transferred to the FASTRIP T5 stripping tank. The stripped material is then moved to the rinse tank, where, if necessary, a final spray rinse can be performed using the ALIT mobile pump.

At this point, the basket containing the stripped and rinsed material is transferred, again with the overhead crane, to the loading and unloading tank, where any final dripping is collected. For a complete and detailed description of the FASTRIP T5 MULTITANK system, please refer to issue 3 of the ALIT ACADEMY Magazine. In this article, we present a new case study featuring a major client which has been stripping in-house frames for approximately 9 months (since April 2023) using the FASTRIP T5 MULTITANK system in conjunction with ALIT Technologies’ chemical products. The company has transitioned from an outsourced pyrolytic stripping process to an internal chemical stripping process, with the external process now limited to rare oversized hooks.

We asked Claudio Puppi, ALIT’s sales technician, to introduce the company involved in our case study.

Figure 1: Sabiana SpA, manufacturer of environmental conditioning devices

“Sabiana SpA (fig. 1) (www.sabiana.it) is an Italian company that conceives, designs, and manufactures devices for environmental conditioning of workplaces and living spaces. It builds equipment and systems for heating and cooling various spaces such as factories, offices, hotels, hospitals, shopping centers, and houses, all based on the most natural element: water. Sabiana’s product range includes air heaters, radiant panels, fan coils, air handling units, recovery units, electronic filters, evaporative coolers, and radiant systems. Established in 1929, Sabiana has grown in terms of business, article quality, and global presence. In 2014, Sabiana became part of AFG (Arbonia-Forster Holding AG), now Arbonia AG, an international technological leader in construction materials. Sabiana SpA has an in-house powder coating facility for applying epoxy-polyester coatings. This coating line produces a significant quantity of coating hooks that need regular stripping. In the past, Sabiana Spa used to rely on an external stripping service for this activity, with hooks collected in special boxes and regularly sent to the external provider.

Claudio Puppi continues saying that ALIT was contacted by the client which was interested in an alternative to pyrolysis. Tests on Sabiana Spa’s hooks were conducted in ALIT’s laboratories, revealing that stripping them with METALSTRIP 2011 at 80°C was feasible. Consequently, ALIT proposed the initial design of the FASTRIP T5 MULTITANK stripping system. This technical proposal was later refined to fit the client’s space, the geometries of the overhead crane, basket, and lifting system, with valuable input from Engineer Vincenzo Denti, Sabiana’s director, who prepared the work area. In April 2023, the FASTRIP T5 MULTITANK system was installed, and the client began internally performing regular chemical stripping of hooks. The management of this process was entrusted to Dr. Marco Colombo, a chemist at Sabiana SpA.

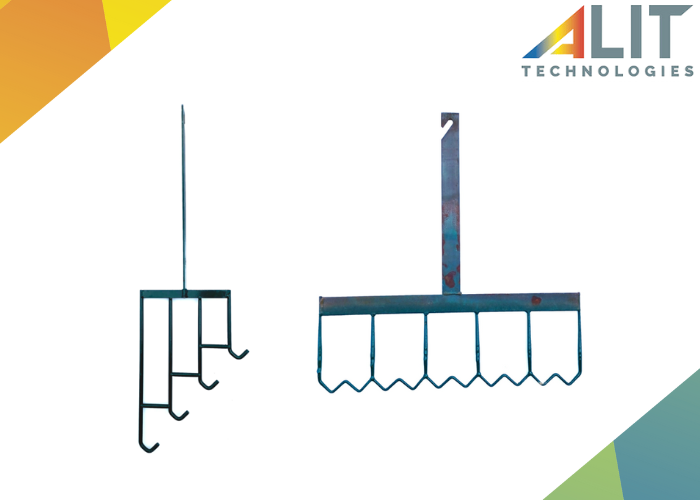

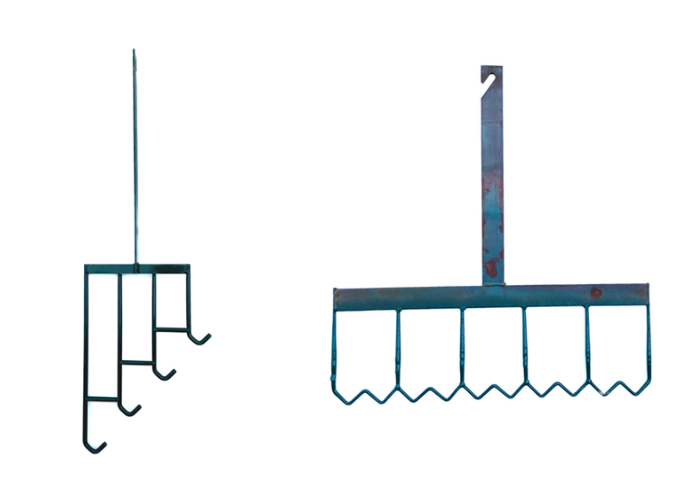

We asked Claudio Puppi for details on the process, and he specified that Sabiana SpA strips about 3 baskets of hooks per week, with variable cycle times ranging from a minimum of about 2 hours to a maximum of about 7 hours for hooks with very thick paint layers (fig. 2). The product used is METALSTRIP 2011 by ALIT TECHNOLOGIES Spa, maintained at a temperature of 80°C.

Figure 2: Sabiana hooks painted with very thick paint layers

After the stripping tank, the basket is transferred from the overhead crane to the rinse tank, where first immersion and then spray rinsing are performed using the ALIT mobile pump or a small pressure washer connected to the same rinse tank (fig. 3).

Figure 3: Spray rinsing of stripped hooks in the client’s facility

This minimizes water consumption, estimated at about 3000 litres per year. Despite stripping about 5000 kg of hooks annually, the consumption of stripping agent is low, approximately 1500 kg per year.” Claudio Puppi continues stating that these numbers have fully satisfied the client, who can now internally carry out stripping operations without:

• Managing the logistics of shipping and receiving hooks to the external stripping service, as was done previously.

• Worrying about the risk of thermal embrittlement of hooks, which was inherent in the previous pyrolytic process.

Following the introduction of FASTRIP T5 MULTITANK, the client has experienced the following benefits:

• Improved stripping quality.

• Fewer coating defects on final products.

• Hooks no longer damaged by the thermal stress generated by the pyrolytic process.

• Certification of hooks and their load-bearing capacity no longer deteriorates, as it did with the previous pyrolytic technology.

• Overall savings in the stripping process in terms of time and money.

| Paint stripping product | Metalstrip 2011 |

| Activator | Aktivator 2550 |

| Temperature | 75-80 °C |

| Treated parts | Epoxy-polyester powder coated hooks |

| Average basket load | approx. 40 kg of frames/basket |

| Average paint stripping time | 7 hours |

| No. basket/week | 2-3 |

| Estimated total annual paint stripper consumption | Approx. 1500 kg of product/year |

| Amount of waste water/year | Approx. 3000 kg of water/year |

Claudio Puppi emphasizes that this case study is another confirmation of the effectiveness of the FASTRIP T5 MULTITANK system and ALIT’s approach to the customer. When faced with an initial technical request, we conduct laboratory tests and work together with the client to design the best customized system solution (fig. 4). Precise, fast assembly is then carried out as ergonomically as possible, concluding with regular supplies of ALIT chemical products and a consistent service for analysing the stripping baths. Following this approach precisely, ALIT has achieved customer satisfaction with Sabiana SpA and is now ready for the next case study.

Figure 5: Complete FASTRIP T5 MULTI TANK System installed at Sabiana SpA